Introduction

Introduction

It is only in the last 150 years that we have such strong standardization of the beehive. The ubiquitous white boxes we associate with beehive are called “Langstroth Hives.” and lend themselves particularly well to industrial scale beekeeping. During the end of the 19th and early 20th century there was much discourse about different hive systems, which were best for the bees and which would produce the most honey.

We are now at a moment when many are interested in the de-industrialization of beekeeping and the pursuit of honeybees for their health and well being as much as for the products of their hive. Beekeepers and innovators are looking at how to support bees, letting them build their comb and live their lives as they would with little human intervention. To these ends beekeepers are coming back to some old ideas that work.

Top Bar Hive

I started working with top bar hives in 1996. At that time they were known as the Kenyan Top Bar Hive or KTBH, because they had been developed by the Peace Corps for use in cottage industry beekeeping in Africa where people would benefit from a low input, high-output system. Top Bar hives were not new, they are an updated version of a very old idea. In the late 1990s, TBHs were considered extremely fringe and indeed if you wanted to use one, you had to build it yourself. The good news was that this was easy and inexpensive.

The Top Bar concept is simple — an open box with bars that sit across it. The bars are the right width so that the bees build in the middle of the comb while leaving a space between the combs (called “bee space”). This dimension is 1-3/8 to 1-1/2 inches. The bars often have a flange in the center, called a comb guide, that the bees attach to. The bees then build their combs down from the bars, filling them out to the size and dimension of the box. Each bar with its comb attached is called a “paddle.”

The top bar hive is horizontal and the bees arrange things in a regular fashion within them in relation to the entrance. The usually put a comb full of food stores right at the door, followed by brood and behind that any honey stores.

TBHs allow the bees to build naturally, adjusting cell size for the minute differences needed for worker brood, drone brood and food stores. Once bees regress to their natural comb size it is said that it is a natural mite control, as the small cells mean less time inside the brood cell and less space for the mites to proliferate as their life cycle also takes place inside the brood cell.

To this day, even though there are now a half dozen companies that specialize in building and selling top bar hives, there is no standard sizing for top bar hives, which can be seen as a downside. As well, because the combs are not enclosed in a wooden frame, they can be more fragile to work with for those who are not accustomed to them.

Overall, in spite of some drawbacks the TBH is an excellent choice for backyard beekeepers, particularly those in more temperate or moderate climates.

Warre Hive

The Warre Hive was developed and promoted by the Abbey Warre, a French Abbot, in the 1930s, a time of heated discussion about which hive was “the best” throughout Western Europe.Warre called his hive “The People’s Hive,” and the book he published is called “Beekeeping For All.” His was a hands-off beekeeping system that was healthy for the bees and easy enough for anyone to keep a couple hives.

The Warre hive is similar in dimension to the hollow of a tree truck. Although there are stacking boxes, they are much smaller than the Langstroth Hive and the walls are thicker. Each box has 8 slender bars that the bees build down from, attaching the combs to the straight sides on the inside of the box.

Probably the biggest difference between the Warre hive and other systems is that instead of stacking additional boxes for honey on top (supering), additional boxes are placed underneath (nadiring). This mimics more closely what bees do in nature.

Bees naturally start building on the top surface of whatever cavity they are in and continually build down to fill the space. As they build down they keep nectar above their brood. Any nectar not used for brood is cured into honey, so that as they build the honey stores are left above and the brood is below. In winter, when forage is low, the bees eat their way back up the honey ladder.

In the Warre system of beekeeping a box is added below the brood when the bees run out of space and a box of honey is taken off the top of the hive when the bees have plenty stored. This means that the hive is functionally managed only once a year.

Any time you open the hive to manage the bees, it takes them over 24 hours to regain their temperature and scent communication, which is a great set-back for them. The Warre system recognizes this and minimizes interruption of the bees at work.

Foundationless and/or reverse order Langstroth Hive

Some folks are committed to the Langstroth system but nevertheless would love to implement a more natural approach. This can be done easily in a number of ways.

- Remove or leave off foundation. Particularly plastic frames and foundation are difficult for the bees. These do not vibrate to carry communication in the same way as wax comb does. Given their choice bees will build first in empty space, second on wax foundation and last on plastic. Allow bees to build their comb naturally within the Langstroth frames means they can adjust cell size for their different needs.

- Leave off the queen excluder. The bees know how much brood they need and will still store honey above the brood in the long view. If there is brood in the honey area, this is what the bees need and we can leave them that honey.

- Nadir instead of super. This is harder with the larger Langstroth boxes, but there is no reason you can’t set your boxes one by one to the side and put a new box underneath so the bees can continue to build down. Many treatment free Langstroth beekeepers use all medium boxes, to make things simpler and lighter.

Sun Hive

Comfort Hive

Golden Hive.

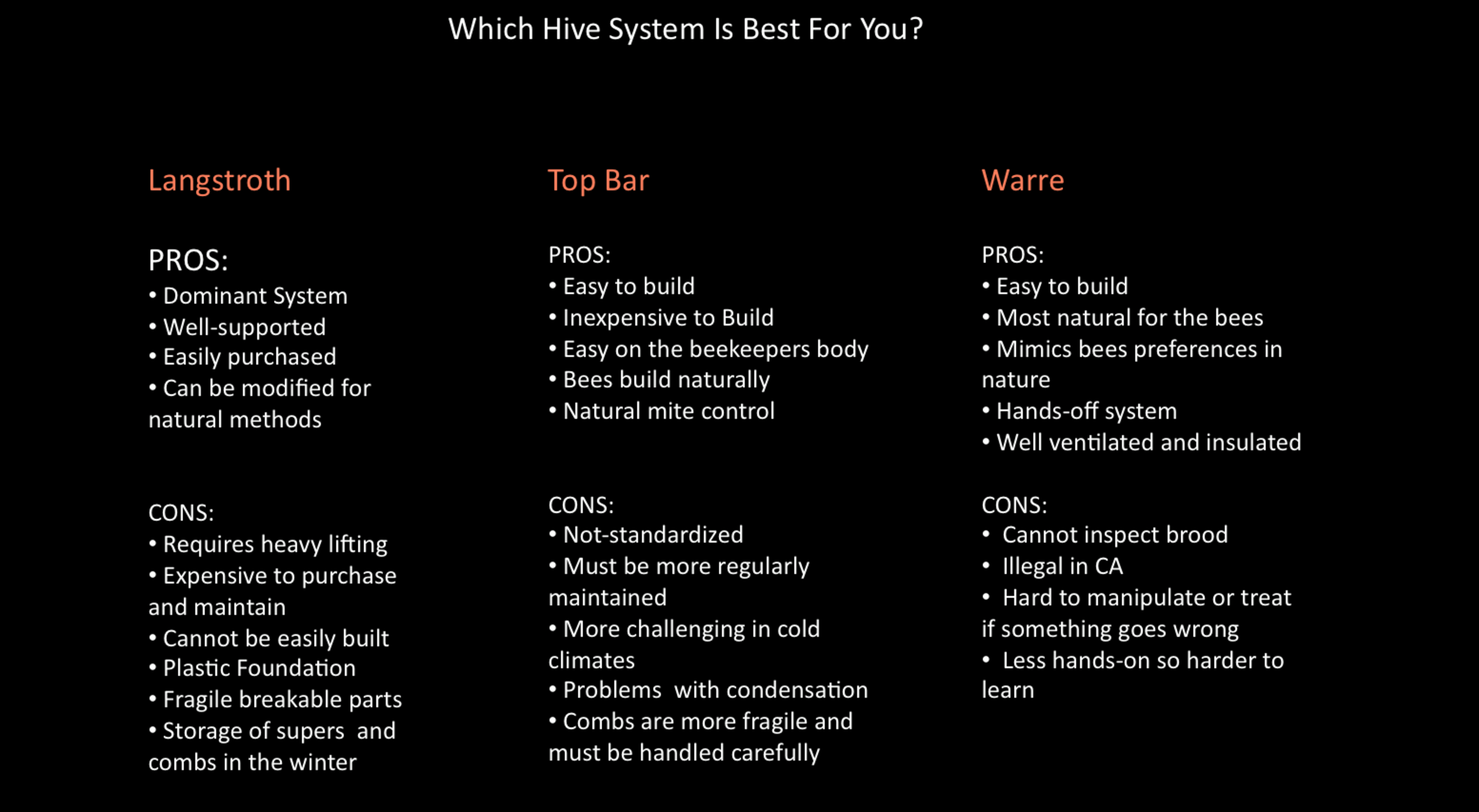

Here are three better known systems compared: